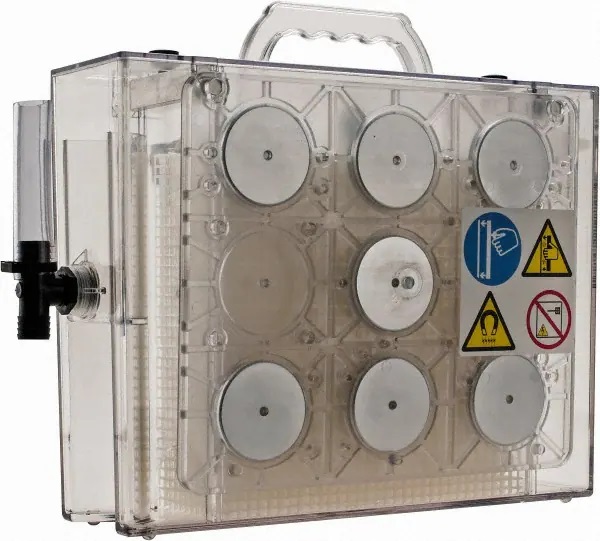

NexJen C-Thru Separator

$645.00

A revolutionary, patented filtration and oil separation unit with the unique features of being transparent, compact, and able to hang from a machine via a magnetic base. Standard Package includes C-Thru Separator, 115V/60Hz pump, hoses, magnetic base, and 3-ball float. OPTIONAL Package (for same price) includes C-Thru Separator, 115V/60Hz pump, hoses, magnetic base, and perfect skim compact float. This substitutes the compact float for the 3-ball float.

NexJen C-Thru Separator

Description

The C-Thru® Separator is a unique, patented unit designed to remove solid and liquid contamination from coolants and cleaners throughout the metalworking and pretreatment industries. Contaminants such as hydraulic oil, way lube, and rust preventatives continually enter the metalworking and cleaning fluids from the machine itself or parts being processed in the application.

Features

The C-Thru® Separator is compact and portable with installation made simple by attaching directly to the machine utilizing the magnetic base provided. A float connected to a pump (electric or air) draws the contaminate oil from the surface of fluid. The tramp oil is separated and remains in the C-Thru® Separator where it can be drained off by opening the valve.

Benefits

Extended fluid life

10 times more efficient then belt, disk, or rope skimmer

Reduced waste disposal

Increased tool life

Simple and quick installation using magnetic base

No consumables

Compact

No floor space utilized

Easy to clean

Patented, transparent design

The C-Thru® Separator is manufactured via injection mold producing a seam free, extremely durable tank. The tank has withstood being dropped from over 15 feet onto cement, hit with a 8 pound sledge hammer and driven over by a 10,000 pound truck. The chemical resistance of the resin is outstanding as it can withstand aggressive chemicals such as sodium hydroxide, sulfuric acid, mineral oil, kerosene, diesel fuel and isopropanol.

Submersible electric pump:

Maximum Temperature: 100°F (38°C)

Applications: Metalworking fluids

Specifications:

Dimensions: Length = 18.8” (478mm)

Height = 14.3” (363mm)

Width = 4.7” (119mm)

Operating volume: 2.64 gallons (10 liters)

Required access to

reservoir: 8.88” (225mm) for standard float

Recommended Accessories & Replacement Parts

The NexJen replacement pump for the NexJen C-Thru Separator is the beckett Versa Series Model G325A epoxy encapsulated submersible pump.

The NexJen Perfect Skim is an optional compact skimmer device that attaches magnetically to the bottom of the tank. Includes ½” barb fitting for tubing. It is designed for areas where the standard three ball float cannot work effectively.

The Little Giant Model 2E-38N submersible pump motor is 100 watt/1.7 amp compared to the 50 watt/.8 amp Beckett Versa pump motor.

Related products

The Zebra Muscle™ Flexor™ Coalescer Z17 tramp oil separator will aerate, filter, and separate coolant from tramp oil so that your coolant lasts longer. Can be run 24 hours a day - 7 days a week without overflowing tramp oil container!

Abanaki Oil Boss Magnetic Mount Tramp Oil Skimmer picks up hard to remove oils that conventional skimmers leave behind. COMPLETE! Our price includes the pump, float, mounting bracket, and hoses.

The air-driven Keller TKO Tramp Oil Skimmer rapidly sweeps out tramp oil, cleaning and aerating the entire sump.