Groz Plus Deluxe Venturi Mixers for Metalworking Fluids (Coolants, Cutting Fluids) and Cleaners

$215.00

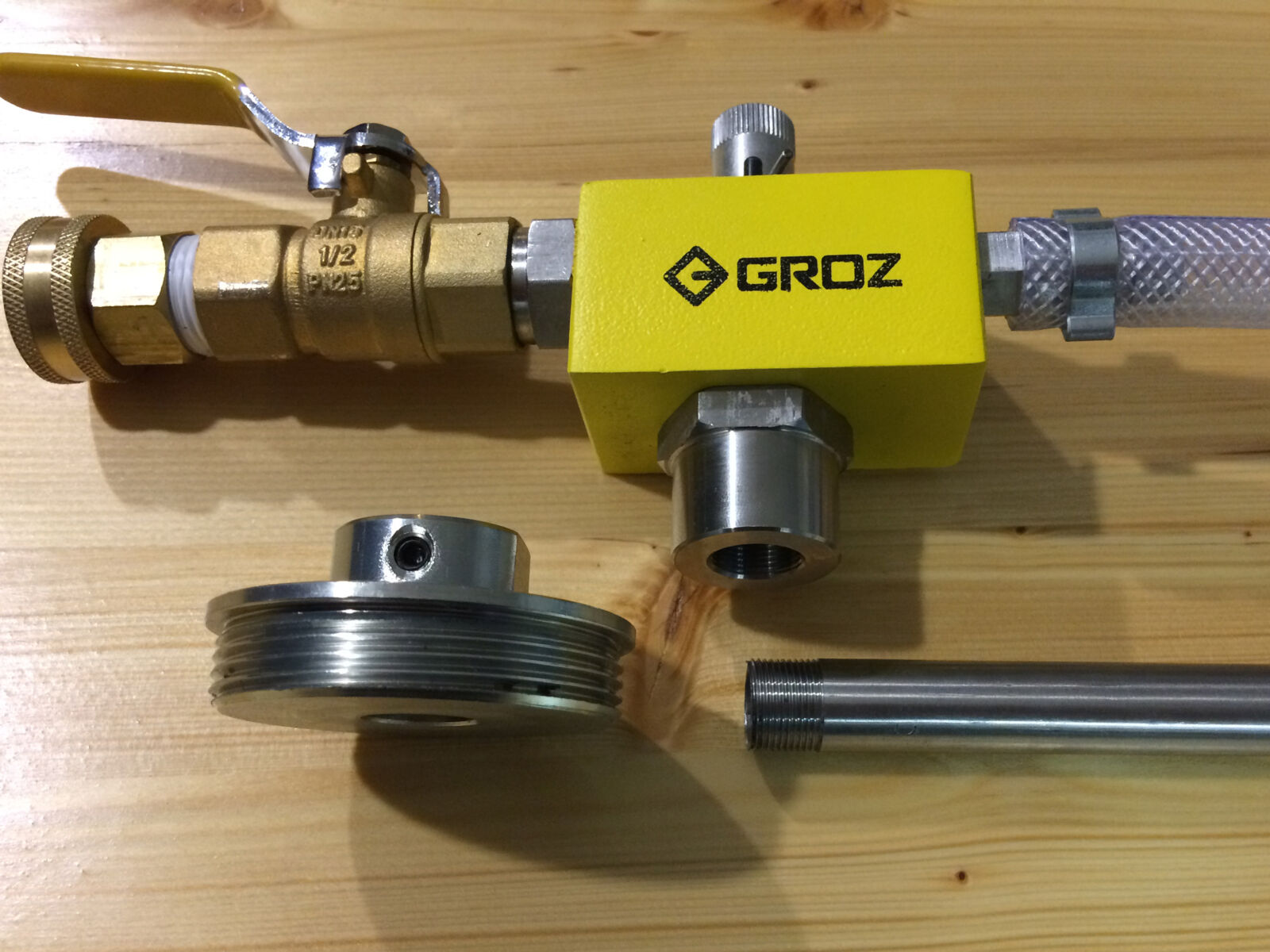

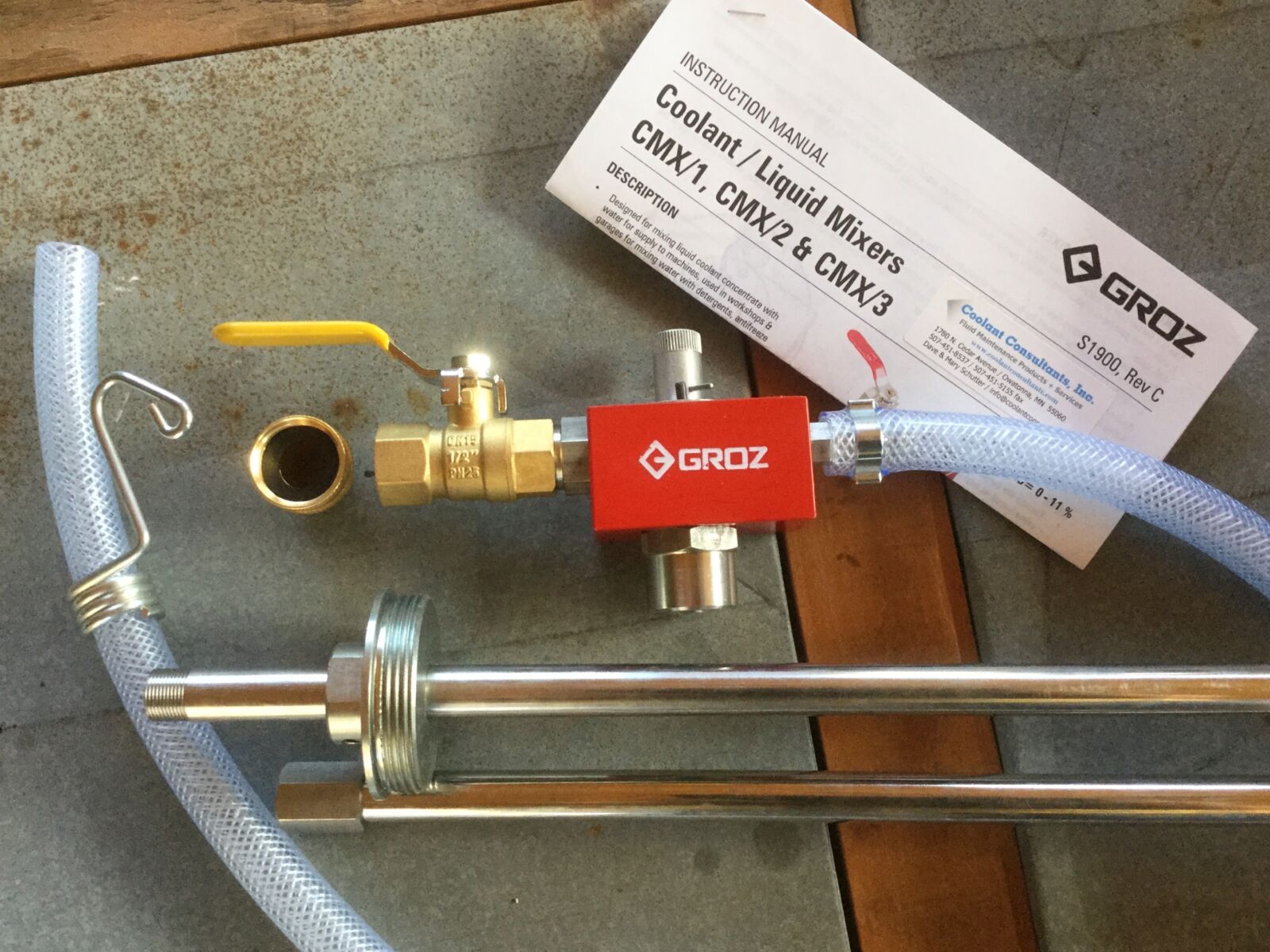

Groz Plus Coolant Mixers use a rotary disk valve allowing adjustment of the mixing ratio through a simple turn of the knob. Includes 3/4″ female garden hose adapter and adjustable stainless steel intake pipe (not included with mixers sold by other online sellers).

Groz Plus Deluxe Venturi Mixers for Metalworking Fluids (Coolants, Cutting Fluids) and Cleaners

Introducing the world’s most advanced coolant mixers that are virtually maintenance free, highly accurate, and provide easy and fast adjustment. Groz coolant mixers use a rotary disc valve which is precision CNC machined from stainless steel. Other venturi coolant mixers are designed with either a needle valve or set of mixing jets. These designs can be time consuming to adjust, have too many parts, and/or are prone to blockage. The Groz Plus Coolant Mixer’s rotary disc valve is highly accurate, and their compact construction and minimal parts make these coolant mixers easy to install and highly reliable.

Groz has made specific modifications on these mixers for Coolant Consultants, lengthening and switching the suction tube from plastic to a two-piece threaded stainless steel pipe. The stainless steel pipe screws in securely and will not fall off into your drum! The adjustable collar allows for different height drums or use only one piece with 5-gallon pails.

FEATURES

-

- Lightweight aluminum body

- Driven by water pressure

- Full flow brass ball valve with 2 back flow preventers

- Variable adjustment of mixing ratio through a simple turn of the knob!

- Stainless steel pick up tube (34″ length) threads directly into the mixer body

- 2″ bung that fits directly on 55-gallon coolant drums

- Mixing Percentage (0-9% yellow), (0-11% red), 4.8 GPM – see NOTE below!

- 3/4″ female garden hose brass swivel adapter included

- Wetted Components: Aluminum, stainless steel, brass, acetal, nitrile rubber

Link to Groz Promotional Video

2.5 minute YouTube video shows how the Groz coolant mixers work. Mute the music…

CAUTION: These units cannot operate with any back pressure, so they can only be used to fill a pail or nearby container. The outlet hose cannot be restricted or used to shut off the mixer. The outlet hose must NOT be connected to any device that can restrict the flow. This means NO sprayer devices, in-line systems, or piping overhead lines.

NOTE: The stated mixing percentages are based on mixing liquids with the viscosity of WATER. The viscosity of the coolant will affect the maximum percentage that can be achieved.

| Specification | Red CMX/1+ | Blue CMX/2+ | Yellow CMX/3+ |

|---|---|---|---|

| Mechanism | Venturi Type | Venturi Type | Venturi Type |

| For Use With | 55 Gal (205 Litre) Drums | 55 Gal (205 Litre) Drums | 55 Gal (205 Litre) Drums |

| Water Inlet | 1/2″ NPTF male | 1/2″ NPTF male | 1/2″ NPTF male |

| Adapter Included | 3/4″ FGH | 3/4″ FGH | 3/4″ FGH |

| Incoming Water Pressure | Minimum 50 PSI recommended | Minimum 50 PSI recommended | Minimum 50 PSI recommended |

| Bung Size | 2″ | 2″ | 2″ |

| Hose Length | 39.37″ (1 m) | 39.37″ (1 m) | 39.37″ (1 m) |

| Suction Tube O.D. | 0.62″ (16 mm) | 0.69″ (17.6 mm) | 0.62″ (16 mm) |

| Application | Metal Working Fluids | Soap Solutions, Antifreeze | Metal Working Fluids |

| Mixing Ratio | 0 to 11% | 0 to 57% | 0 to 9% |

| Capacity | 1100 Litre per Hour (290 Gallons per hour) | 1250 Litre per Hour (330 Gallons per hour) | 1100 Litre per Hour (290 Gallons per hour) |

Related products

Groz Plus Anti-freeze and/or Detergent Venturi Mixers use a rotary disk valve allowing adjustment of the mixing ratio through a simple turn of the knob. Includes 3/4" female garden hose adapter and adjustable stainless steel intake pipe.

Economical HydroMaster™ venturi mixers automatically mix coolants and liquid cleaning and sanitizing concentrates with water and dispense the diluted solution into any container.

Hydro Systems Streamline dispensers in stainless steel cabinets dispense a wide variety of automatically diluted solutions at the touch of a button with 2, 3, and 4-button models for many applications.