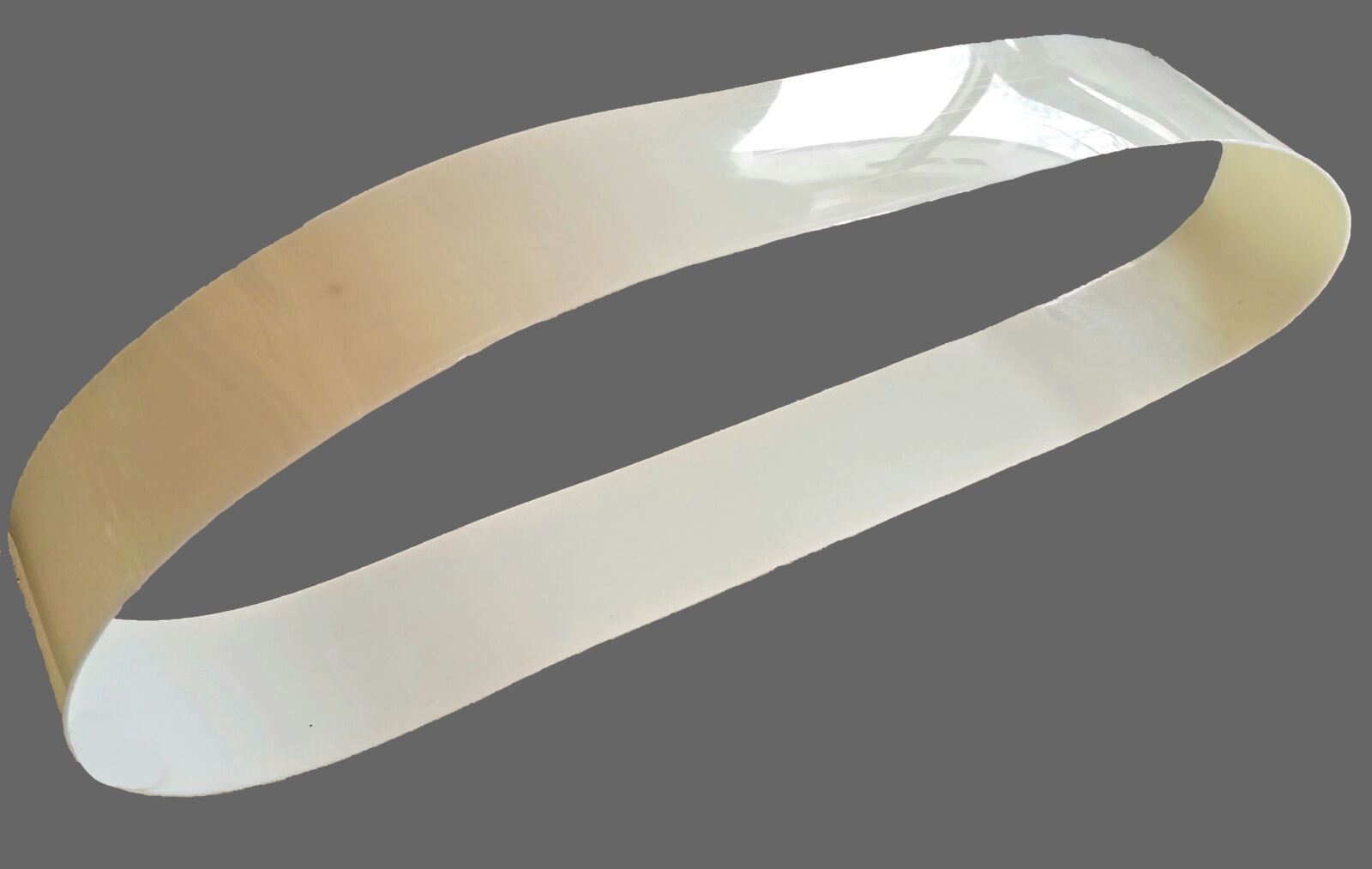

Abanaki Mighty Mini Replacement Belts

$90.00 – $163.00

Abanaki Replacement Skimmer Belts, 1″ or 2″ wide, available in reach lengths of 6″, 12″, 18″, and 24″

Abanaki Mighty Mini Replacement Belts

Standard Poly Belts

Reinforced to resist stretching, able to withstand reasonably high temperatures (up to 170°F), and textured to retain a small amount of oil, thus drawing more oil to itself on subsequent passes. Used where rust inhibitors and temperature are a component of the wash water or where UV sensitivity is an issue.

The polyester mono-filament with polyurethane liner works for demanding applications such as turbulent solutions or explosive atmospheres. An ideal application for the poly-belt is oil remediation using existing monitoring wells. It is also recommended for excessive long distances to pull heavy oils with no stretching. The poly-belt has an operating temperature range between 14°F(–10°C) and 170°F(77°C) continuous. The poly-belt is also effective for picking up certain types of floating emulsified oils.

Elastomer Belts

Can handle abrasive and harsh environments. Used where rust inhibitors are a component of the wash water. The specially formulated elastomer is more attractive to oil and repellent to water than competitive products. It is an extremely durable material, able to withstand rough handling during installation and maintenance. The elastomer belt is ideal in applications where abrasive particles are present or when physical abuse of the belt is likely. The single material belt will not delaminate and is designed for continuous operation. The ideal temperature range when using this material is between 50°F (10°C) and 140°F (60°C). Elastomer is also UV sensitive, so prolonged exposure to the sun should be avoided.

Corrosion Resistant Steel Belts

One of Abanaki’s most popular oil belt skimmer materials. Works well in most industrial applications where rust inhibitors are not a component of the wash water. The CR steel belt is made from a specially formulated stainless steel alloy that is high in chrome, low in molybdenum, and low in carbon. The CR belt stands up to high temperatures and harsh chemicals. With belts operating continuously for 10 years in some cases, applications for this belt are almost limitless. The only limitations on its use are certain combinations of temperature, pH levels, and type of solutions.

XP Poly Belts

Similar to the Standard Polymer but for higher temperature applications (up to 180°F continuous). It can also withstand harsh chemical environments such as those found in the plating industry.

Related products

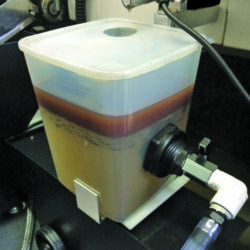

Keller Skimallessor Tank and Magnetic Bracket

Accessories for the Zebra belt skimmers, disk skimmers, and Sidewinder™Tube Skimmers

Wayne Mini-Skimmer™ and MAXI-Skimmer™ Accessories include gravity oil/water separators, adjustable stand, outlet hose extension, timer, and ground fault interrupter.