Keller High Flow Portable Tramp Oil Separators for 10+ Sumps

Keller offers four different size models of the high flow rate portable tramp oil separators for keeping coolant clean in 10+ sumps!

Keller High Flow Portable Tramp Oil Separators for 10+ Sumps

Thinking Portable Tramp Oil Separator?

Get these benefits

- Extended tool life, improved parts finish

- Smoke and odor eliminated

- Multiplied coolant life = Much less machine downtime, greatly reduced coolant purchase & disposal costs

With these exclusive Keller features

- Patented permanent oil separating (coalescing) element, never needs changing

- Rugged high flow 1/2″ air-operated pump provides rapid tramp oil removal, circulates & aerates entire sump

- Compact inlet devices can access any sump

- No electricals – To operate, simply connect 1/4″ compressed air line – All required hoses and fittings provided

- Sets up at a sump in minutes – Requires minimal operator attention – Thousands in service

How the Keller TKO Separators work

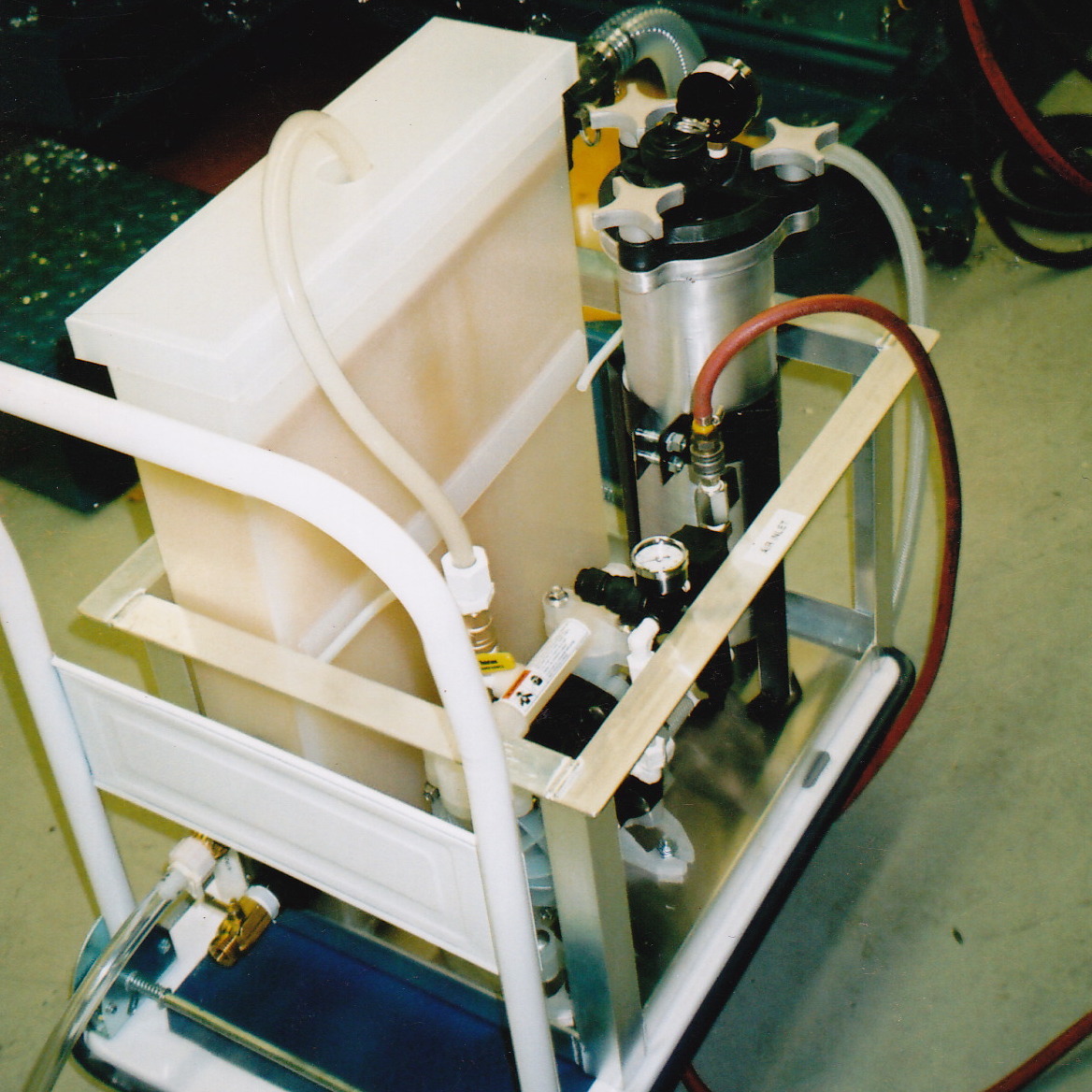

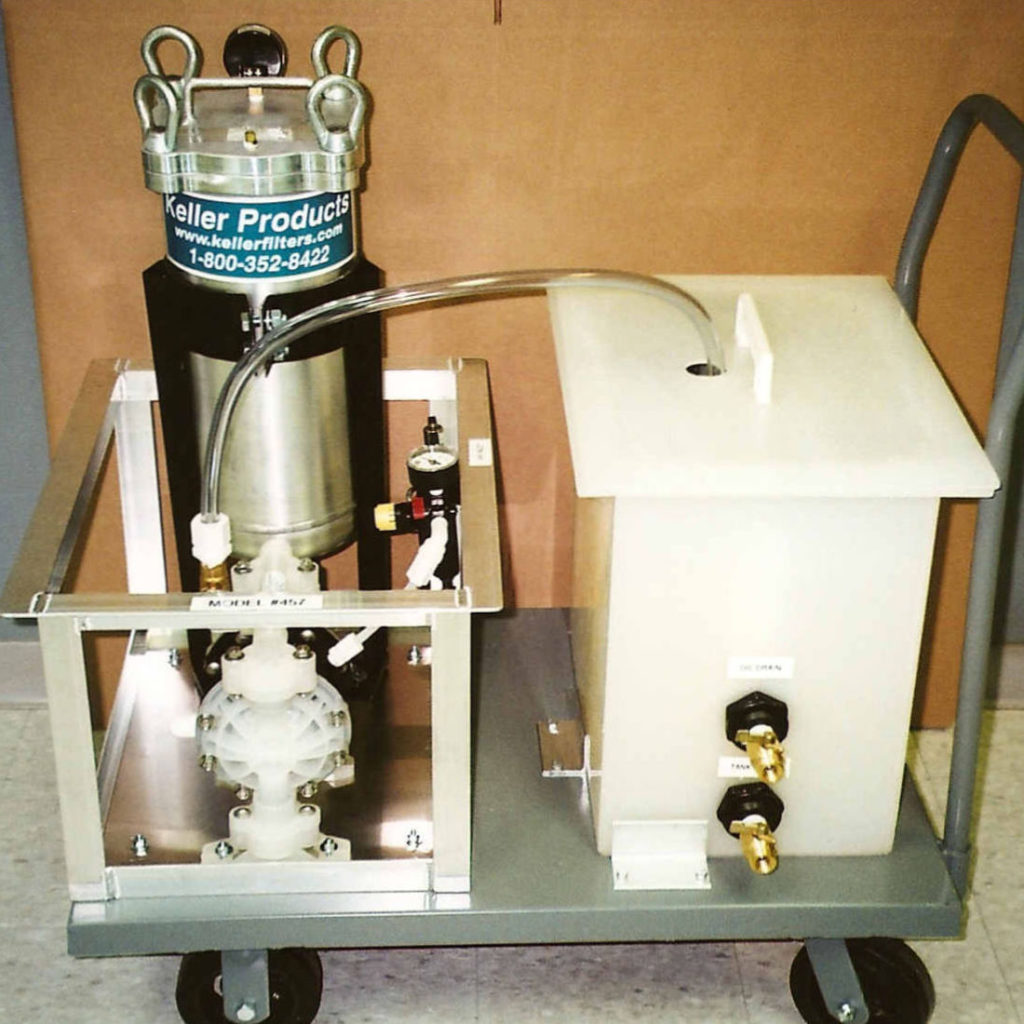

Each separator is supplied with compact inlet devices which can access the surface of any sump through an opening as small as 3″ diameter. The oily coolant is pulled from the sump surface through a solids filter, a high capacity bag filter, which will significantly reduce the concentration of suspended solids in the sump when machining aluminum, plastics, or other light weight materials. The air-operated diaphragm pump has a suction lift of 15 feet and can be run dry or dead-ended without damage. The filtered coolant then flows through Keller permanent plastic oil separated elements immersed in a plastic tank. The coalescing separator elements cause the oil drops to form a layer that rises to the top of the separator tank. The cleaned coolant exits continuously via an overflow port and returns to the sump. The oil layer collected in the separator tank can be drained into a waste oil container by opening the oil outlet valve occasionally, usually once per day. No other operator attention is required.

How to select the Keller Separator for your application

A Keller portable separator can clean a sump in 3 to 4 hours, and then may be moved to another sump and set up in minutes. We recommend that each sump be cleaned once per week. A separator can clean two sumps in a single shift, or 10 sumps per week in a one shift 5 day operation.

The separator model is selected based on:

- the sizes of sumps to be cleaned,

- the relative volume of tramp oil to be removed, and

- the quantity of suspended solids in the sumps.

Selection Chart

| Specification | #315 | #365 | #457 | #465 |

| Coolant Recirculation Rate (gal/hr) | 200 | 200 | 240 | 270 |

| Number of Sumps Treated | 1-8 | 1-10 | 1-10 | 1-10 |

| Sump Size Ranges (gallons) | 40-400 | 40-400 | 90-1000 | 100-2000 |

| Capability for Volume of Tramp Oil | High | High | Very High | Very High |

| Capability for Suspended Solids Load | Moderate | High | High | High |

NOTE: Two RSM-3 Inlet Devices supplied with each model

Model #315 Small Bag Filter/Tramp Oil Separator $3895.00

- 180 gph, 10 gal. separator, cart-mounted, with 5 filter bags

Model #365 Medium Bag Filter/Tramp Oil Separator $4295.00

- 180 gph, 10 gal. separator, cart-mounted, with 5 filter bags

Model #457 Medium Bag Filter/Tramp Oil Separator $4795.00

- 240 gph, 15 gal. separator, large cart-mounted, with 5 filter bags

Model #465 Medium Bag Filter/Tramp Oil Separator $5295.00

- 240 gph, 25 gal. separator, large cart-mounted, with 5 filter bags

Call or email for a quote today!

Specifications

| Model | #315 | #365 | #457 | #465 |

| Dimensions (L x W) | 30″ x 20″ | 30″ x 20″ | 35″ x 20″ | 38″ x 24″ |

| Cart | Included | Included | Included | Included |

| Sump Inlet Devices Provided | (2) each #RSM-3

included |

(2) each #RSM-3

included |

(2) each #RSM-3

included |

(2) each #RSM-3

included |

| UPS shipping weight | 80 lbs. | 115 lbs. | 140 lbs. | 150 lbs. |

| Size of Oil Separation Selection | 10 gal | 10 gal | 15 gal | 25 gal |

| Type of Prefilter | Small bag | Large Bag | Large Bag | Large Bag |

| Poly Filter Bags Included | 5 | 5 | 5 | 5 |

Installation Requirements: All Models

| Compressed Air Flow Requirement | About 0.5 SCFM |

| Compressed Air Pressure | 20 psig to 100 psig |

| Compressed Air Fitting | 1/4-inch NPTF |

| Electricals | None |

INSTALLATION GUIDELINES

When setting up a coalescer, the fluid return hose should be located as far away from the oil pick-up as possible. It can also be used to “push” the tramp oil towards the pick-up unit. The oil pick-up needs to be positioned where the most oil is present if possible. The pick-up also needs to float freely with changes in fluid level. It’s usually best NOT to locate the pick-up near the pumps.

When setting up air powered coalescers, the air regulator should be adjusted so the pump is running really fast, then close the small air ball valve before the pump, reducing the air flow until the pump is running as slow as possible to maintain flow and suction at the pickup device. If you adjust the pump speed with the regulator, the pump can stall out or run too fast with slight changes in shop air pressure. The filter should be changed when flow becomes restricted. Sometimes the filter doesn’t look dirty, but has become “blinded off” by fine residues or contaminant coating.

All oil skimming devices should only be run when oil is present on surface. Timers should be used to activate the device after the oil has settled to the surface. Running them 24/7 just wears the motors out prematurely. Coalescers can be run periodically even if oil is not present on the surface in order to keep the coolant moving on an intermittently run machine.

Related products

Additional inlet devices for the Keller TKO and ECO Tramp Oil Skimmers/Coalescers

Keller replacement filters for TKO and portable separators, BA-075 in-line bag filter, and PFA-1002 filtration system